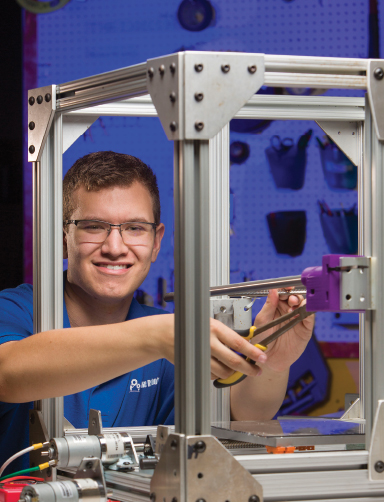

Ben Whipker uses his engineering know-how to solve problems and build machines for the digital age

Ben Whipker goes looking for trouble.

And in his high-tech world, he usually finds it.

“Hands-on and lots of problem-solving; I have to have that to be happy,” Ben said.

Newly 19, he’s grown from a kid who modified the inner workings of his Nerf guns for better performance, to a technical engineer who builds robots and 3D printers, and is launching a startup in Durham’s American Underground @ Main business incubator.

That opportunity arose when Ben, as a founding member of Cary-based nonprofit The Forge Initiative, formerly known as Wake Robotics, presented during the 2014 Leadership Triangle Awards Gala and met Michael Goodmon, head of American Underground and part of the Capital Broadcasting ownership family.

Now Ben and fellow Forge alumni Kyle Mellendorf and Maria Hunter Mackie are at work on a market analysis for The Forge Initiative at American Underground, a center aiming to create tech and leadership development opportunities for youth and adults.

“The team at Wake Robotics has done a fantastic job of growing their work and impact over the past few years, and it showed me that they could build a real organization capable of impacting young people,” said Goodmon.

“We’re in the drawing phase and will begin work on the space this fall,” he said. “We’ve provided an office for them to work from this summer so they can be immersed in the startup community and really understand what the needs are. We are very excited about this partnership.”

Ben says his love of engineering was sparked through participation in the FIRST Lego League, an organization which introduces children to science and technology, then honed at The Forge Initiative.

Founded in 2010 by Ben’s mom and teacher, Linda Whipker, Ph.D., and by Kate Ivers, the competitive group offers hands-on technology exploration, and partners with area organizations including Cary Parks and Recreation to bring STEM activities to the community.

The Forge Initiative is currently raising funds to open a facility in downtown Cary that will offer space to expand the program to more families.

Kitchen Table Science

Ben, also the son of Dr. Brian Whipker, an N.C. State horticultural science professor and researcher, and brother to Jeremy, 9, built his first 3D printer from scratch on the family’s kitchen table, in 2013.

A Prusa 12, it was constructed of parts ordered from around the world.

“It looked like a prism,” Ben said. “It was difficult, and I pulled data and documentation from everywhere. Many of my parts were incompatible. But I discovered that troubleshooting is fun.”

To date, Ben has built four 3D printers and calibrated 11; used and taught laser cutters, CNC machines and lathes; and built and repaired computers as a business.

He’s also employed at At Large Graphics in Cary, where staff have built a large-format, 48-by-24-inch 3D printer with custom nozzles.

“What I saw in Ben is a desire to learn and the experience, through Wake Robotics, to advance our manufacturing through 3D printing,” said At Large owner Al Calderon. “We’re all about the latest technology here, and Ben has helped build and troubleshoot that machine, which is now at viable production status.

“He also works on laser cutting and engraving projects,” Calderon said, “and with electroluminescence,” which provides animated lighting effects. “He has the knowledge, and a great positive attitude.”

Also a gamer, Ben has built a Minecraft server for the Cary Homeschoolers group, and says he likes Minecraft and Skyrim games for their modification opportunities.

“It’s a continuous puzzle,” he said of his work. “There’s always that next thing to solve.”

Ben describes the 3D printing process in a way that draws in his listener, noting that sea turtles are the true test of 3D print quality.

“The turtle’s flat fins are a single layer of print, and its head tests how well your printer is cooling the filament,” he said. “When it comes out of the nozzle, the filament is a sticky goo. It’s up to the fans to cool the printed layer enough for the next layer to have a solid base. Having the temperature off by a single degree, or 5 degrees, makes a difference.”

As part of The Forge Initiative’s mission to mentor, Ben has also become known for nudging students toward solutions.

“Ask Ben. He’ll know,” is a common refrain among the group, on topics from programming to pneumatics.

“I might not know, but apparently I’m good at walking people through it,” he said. “Sometimes others know better, and I know who to go to. Plus, I know the parts it’s OK to break. Some students are afraid of that, but you learn a lot more by failing. It makes it easier to try things outside of your comfort zone.”

His willingness to step out is also paying off in networking skills.

“Now I know I can talk with confidence about the topic,” Ben said, “and maybe it relates to something someone else is doing. I think it’s important to find something to be immersed in, and become an expert.”

Ben, who’s also got a good ear for music, plans to pursue an engineering degree following his busy “gap year.”

“Through The Forge Initiative, I’ve been exposed to various paths that have helped me narrow down what I want to do,” he said. “I can take a gap year to open The Underground Forge, instead of going straight from high school to college, explore what I want to do. I’m happier knowing I can do this.”